Since the term MOTOR Vision refers to the monitoring of “smart” motor starters by Modbus network, all starter types including across-the-line, VFD, or RVSS can provide MOTOR Vision data to the PUMP Vision controller when the proper monitoring devices are installed. The data provided depends on the type of device that is connected to the PUMP Vision controller and is displayed and monitored for alarm conditions and potential failure shutdowns. The data is also available for data logging and monitoring through a SCADA system connected to the controller.

Because the MOTOR Vision starters are connected to PUMP Vision with Modbus, configuration of all the starter’s configurations such as overload trip settings, voltage, RPM, and various alarm trip thresholds and delays are done through PUMP Vision screens. This eliminates the need to open the panel to do complicated setup directly to the starter’s interface.

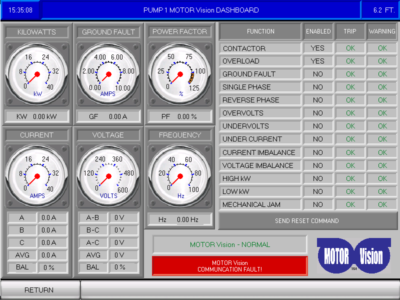

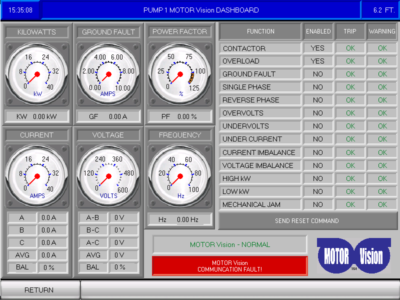

When Eaton Insight motor monitors are connected to the PUMP Vision controllers, a MOTOR Vision “Dashboard” is provided for each pump. While the PUMP Vision PV1200, and PV600 all have different dashboard layouts, each provides all of the same information including actual motor operating information and alarm status. The 12” screen size of the PV1200 controller allow it to display analog meters as well as the digital values that the PV600 displays. A total of 14 possible fault conditions are monitored as well as current, voltage, frequency, power factor, ground fault, kW and more.

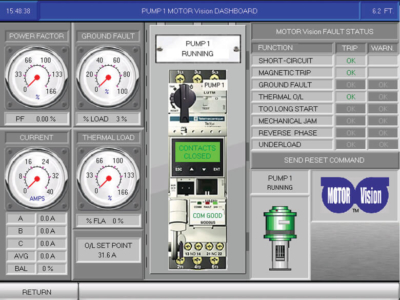

When Schneider Tesys motor starters are connected to the PUMP Vision controllers, a MOTOR Vision “Dashboard” is provided for each pump. While the PUMP Vision PV1200, and PV600 all have different dashboard layouts, each provides all of the same information including actual motor operating information and alarm status. The 12” screen size of the PV1200 controller allow it to display analog meters as well as the digital values that the PV600 displays. It also has a working image of the Tesys motor starter starter display, handle and indicator lights show the actual status of the motor starter without having to open the starter panel door. . A total of 9 possible fault conditions are monitored as well as current, power factor, ground fault, thermal load and more.